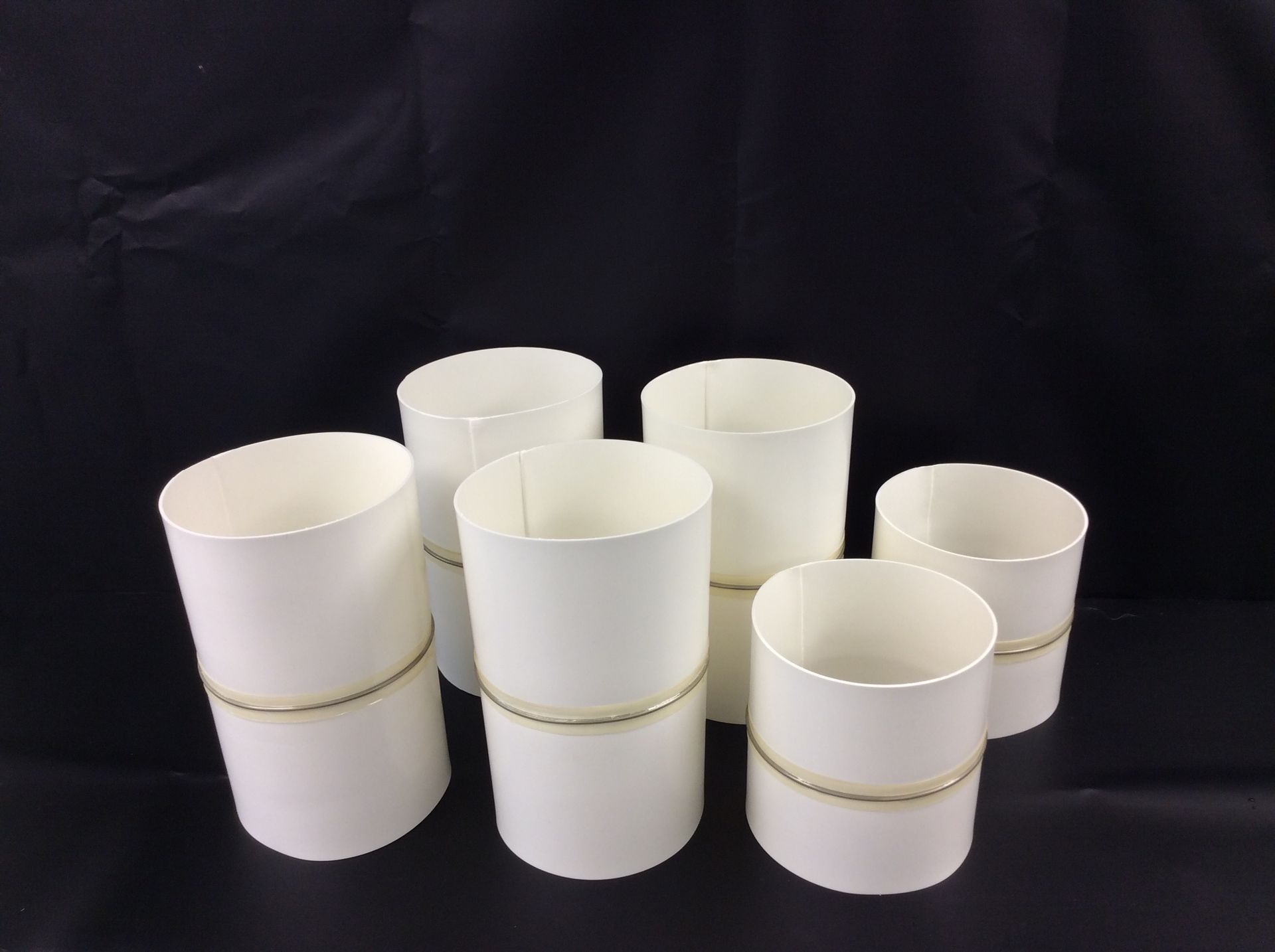

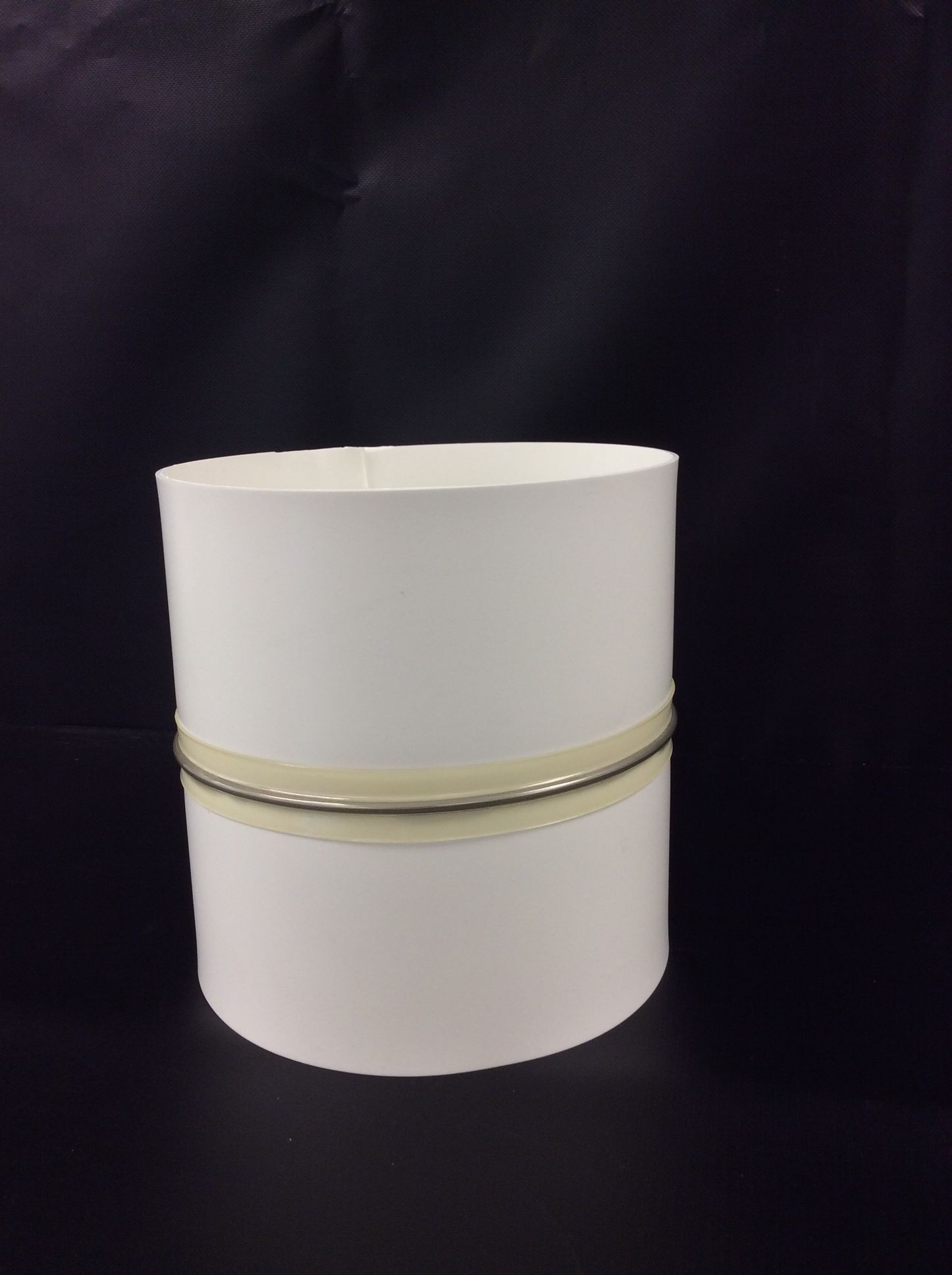

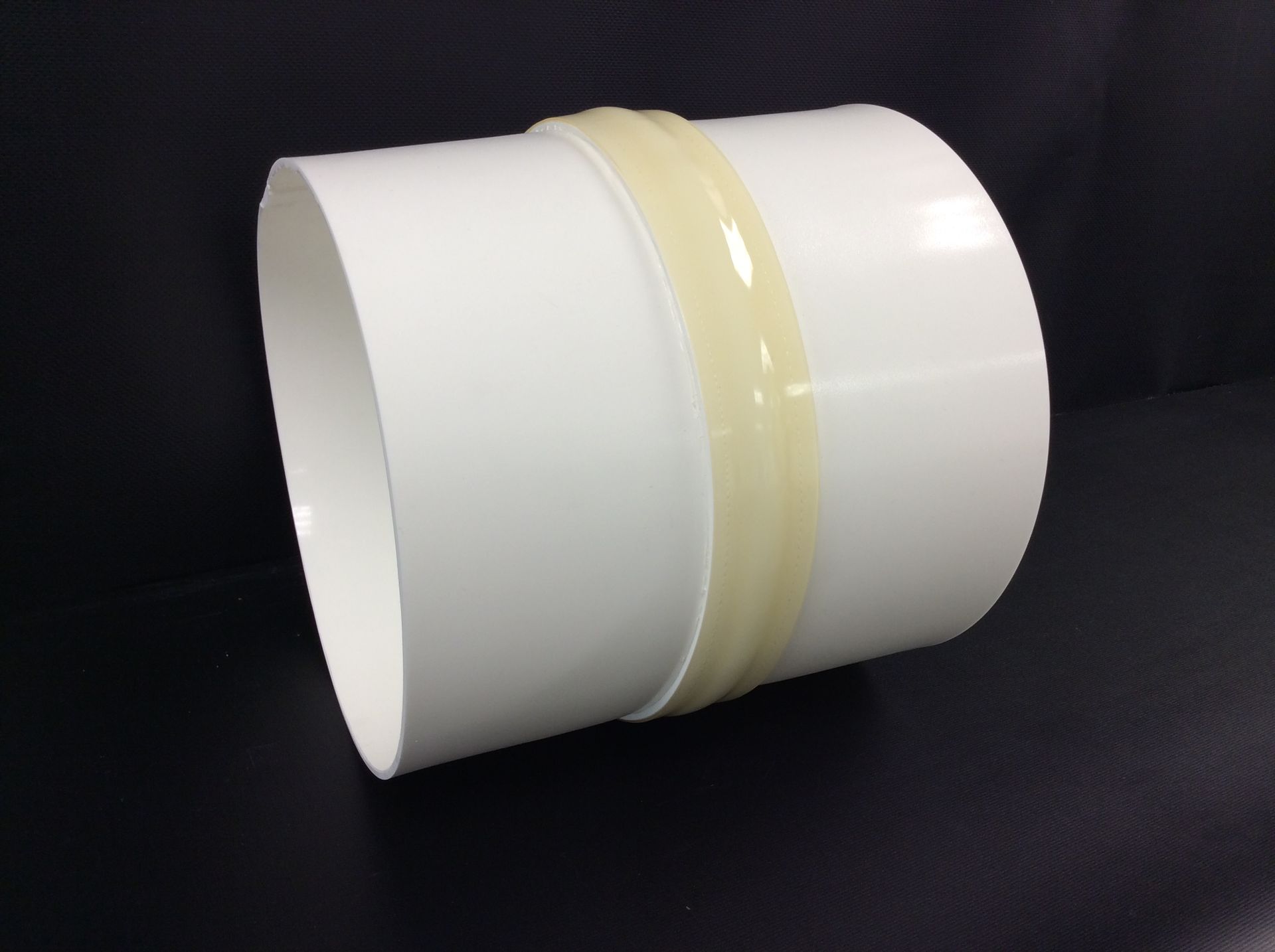

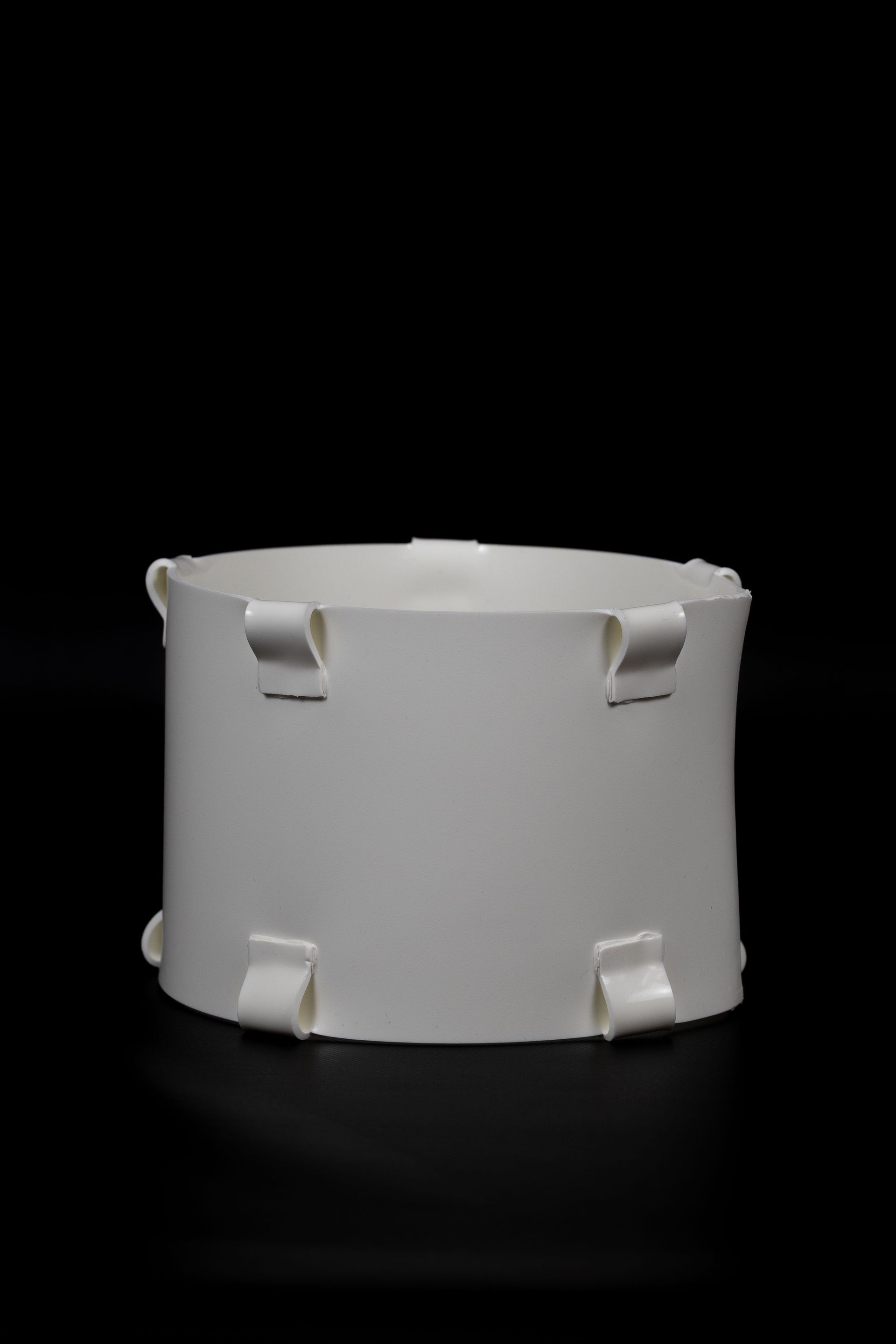

Description:

120W is a white polyurethane material engineered for high performance in flexible connector applications. With outstanding abrasion resistance, food-grade compliance, and excellent flexibility, 120W is ideal for industries requiring sanitary, durable, and ATEX-compliant components. Welded for seamless integrity, it delivers a clean, reliable solution for food, pharmaceutical, and chemical environments.

Documents and Resources:

Reach out to Siftex today to discover more about our 120W products and find the perfect fit for your machinery's needs.

Start Your Custom Project With Us Today

Embark on a journey to innovate and excel with our tailor-made industrial solutions. Connect with our experts now to elevate your operations with customized, precision-engineered products.