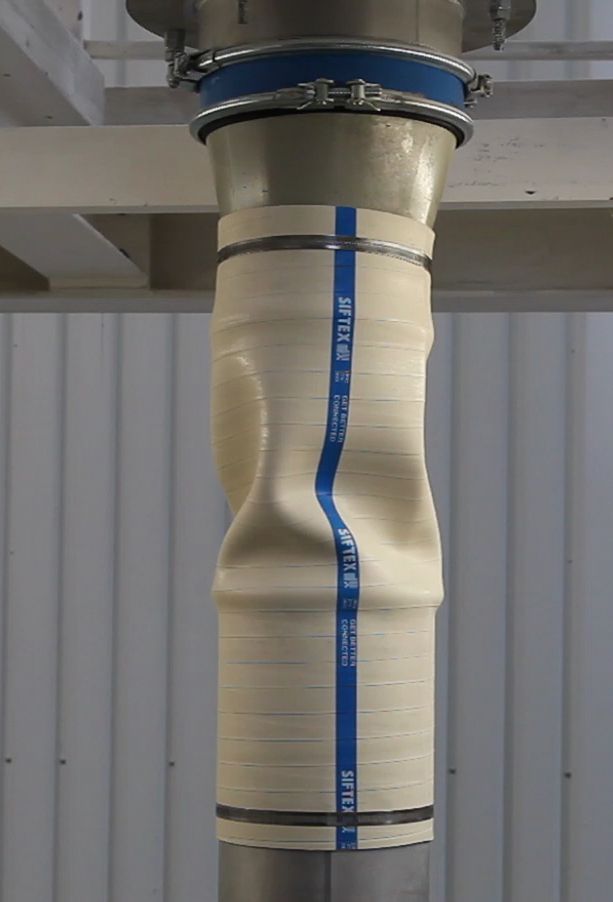

Carboxylated Nitrile Rubber Tubing

Description:

Carboxylated nitrile rubber tubing is formulated for outstanding abrasion resistance, durability and higher temperature resistance. It makes an ideal choice for various industrial applications including sugar and food grade minerals processing. This tubing is available in both FDA and non-FDA accepted rubber compounds.

Documents and Resources:

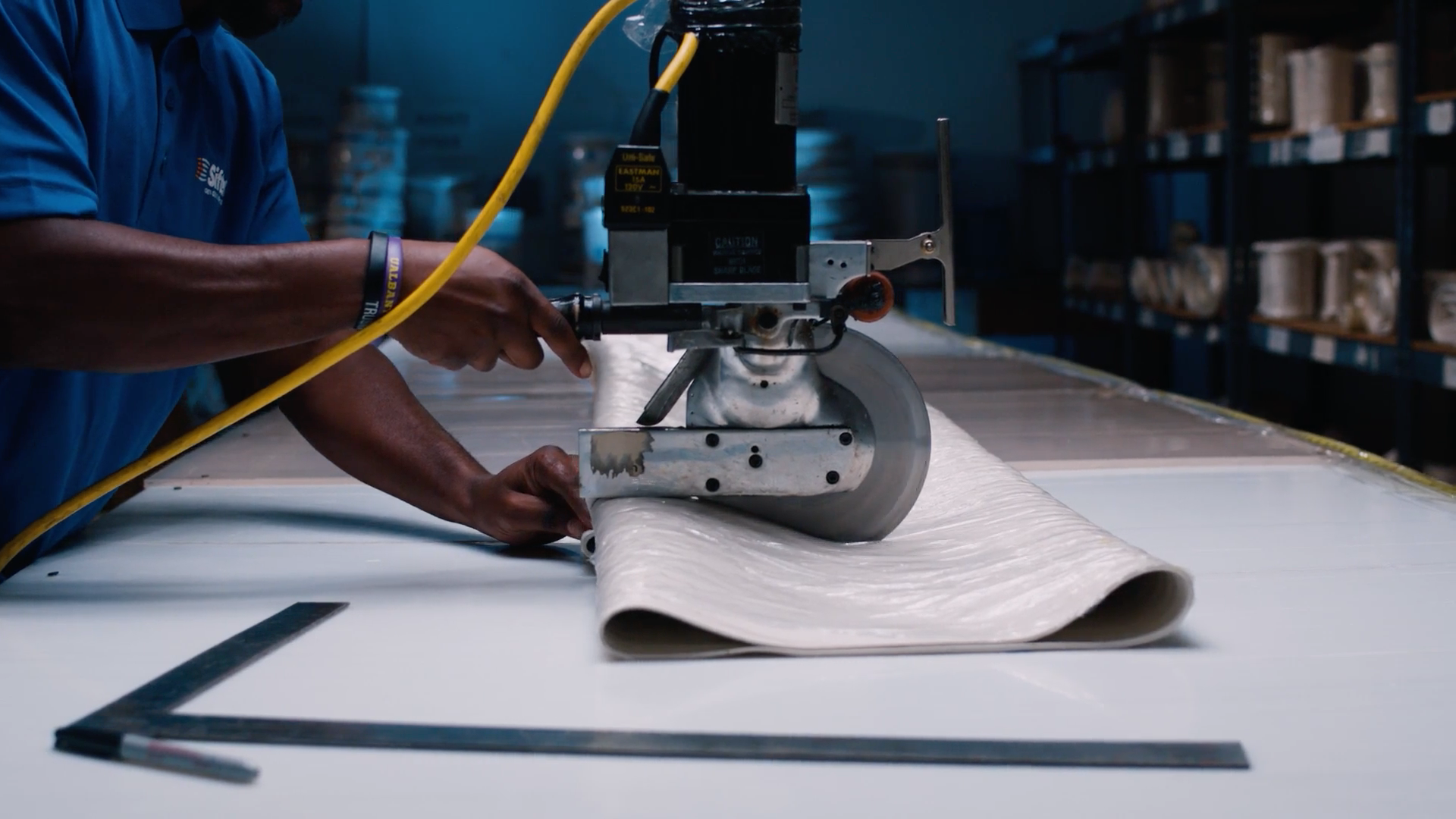

Start Your Custom Project With Us Today

Embark on a journey to innovate and excel with our tailor-made industrial solutions. Connect with our experts now to elevate your operations with customized, precision-engineered products.