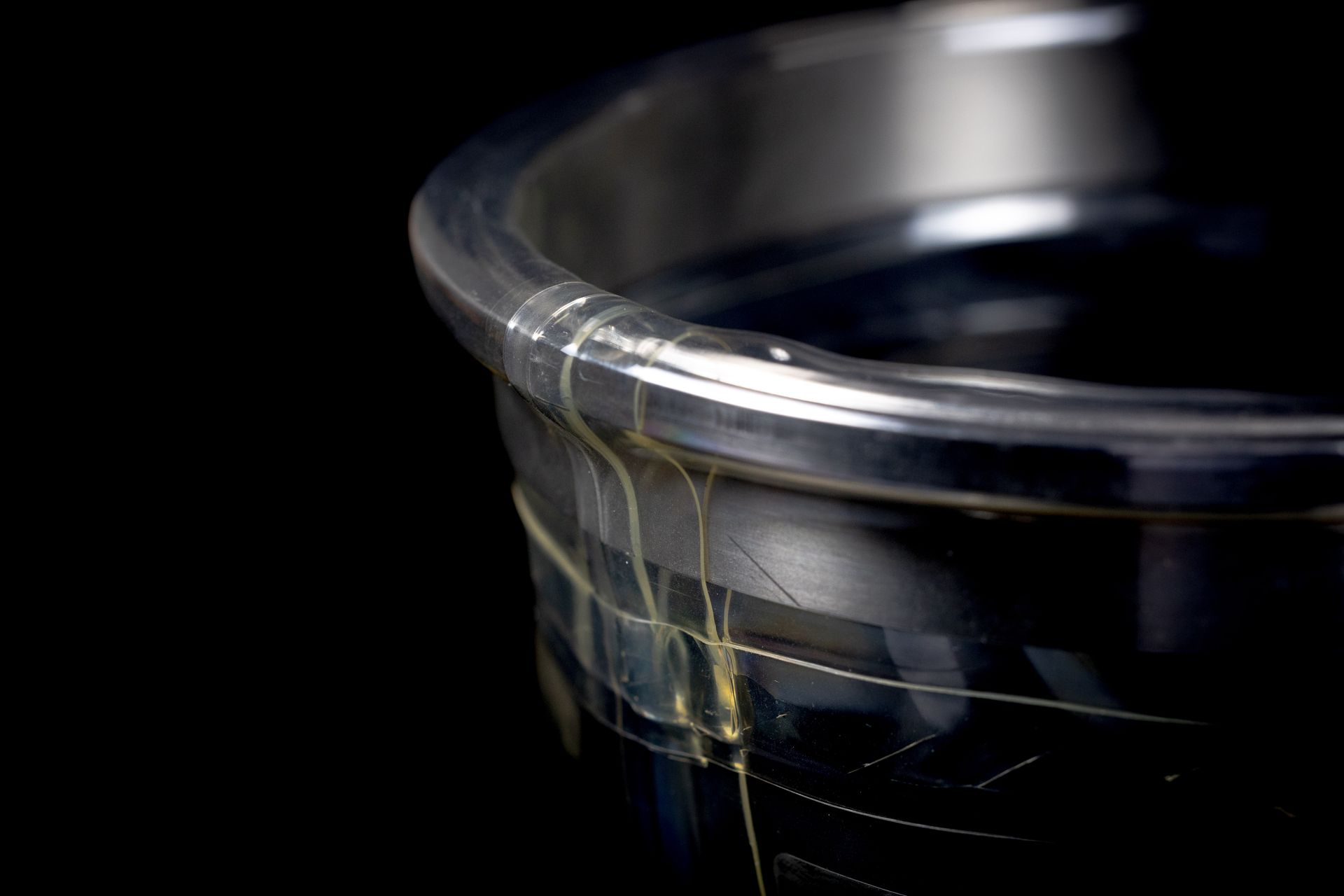

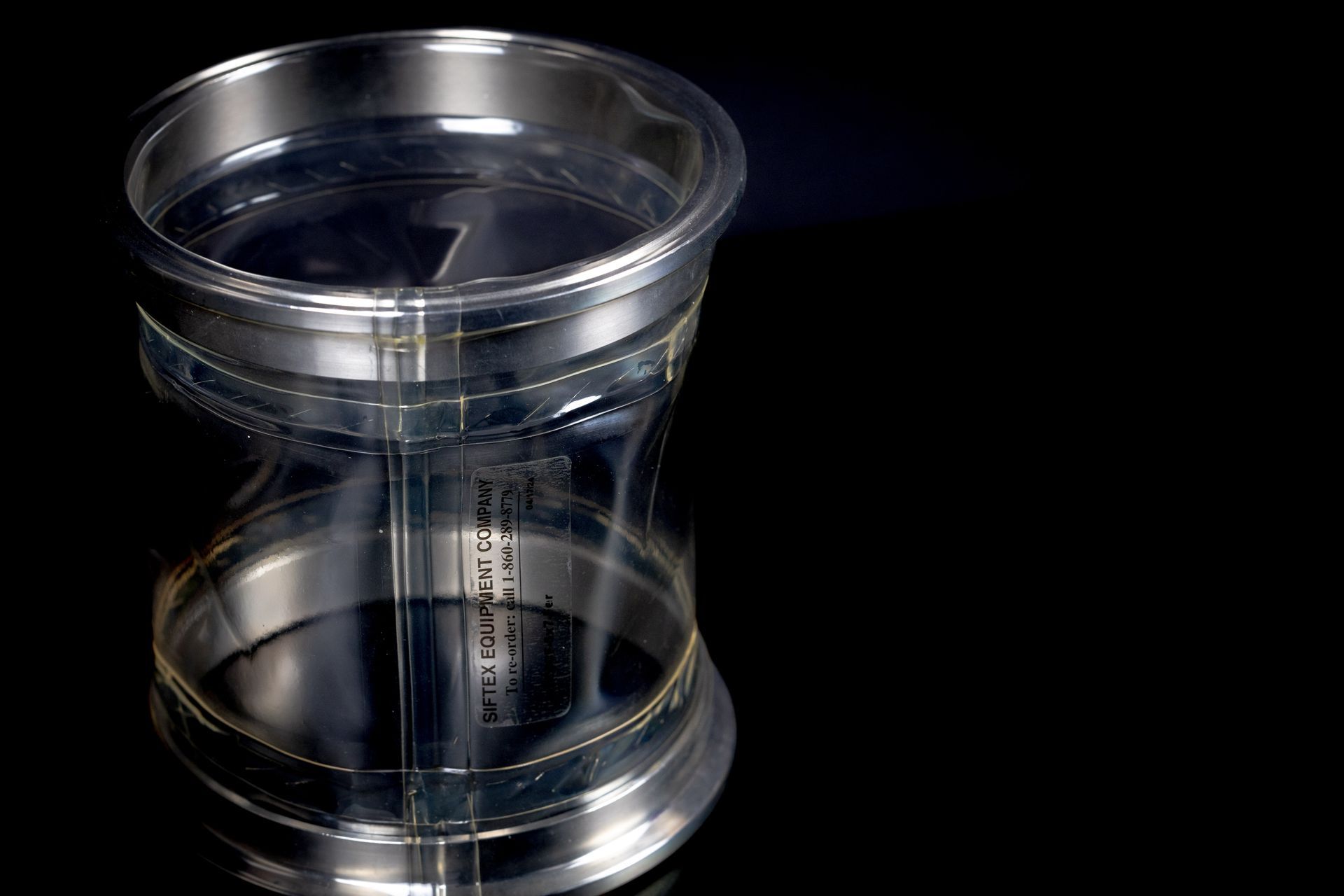

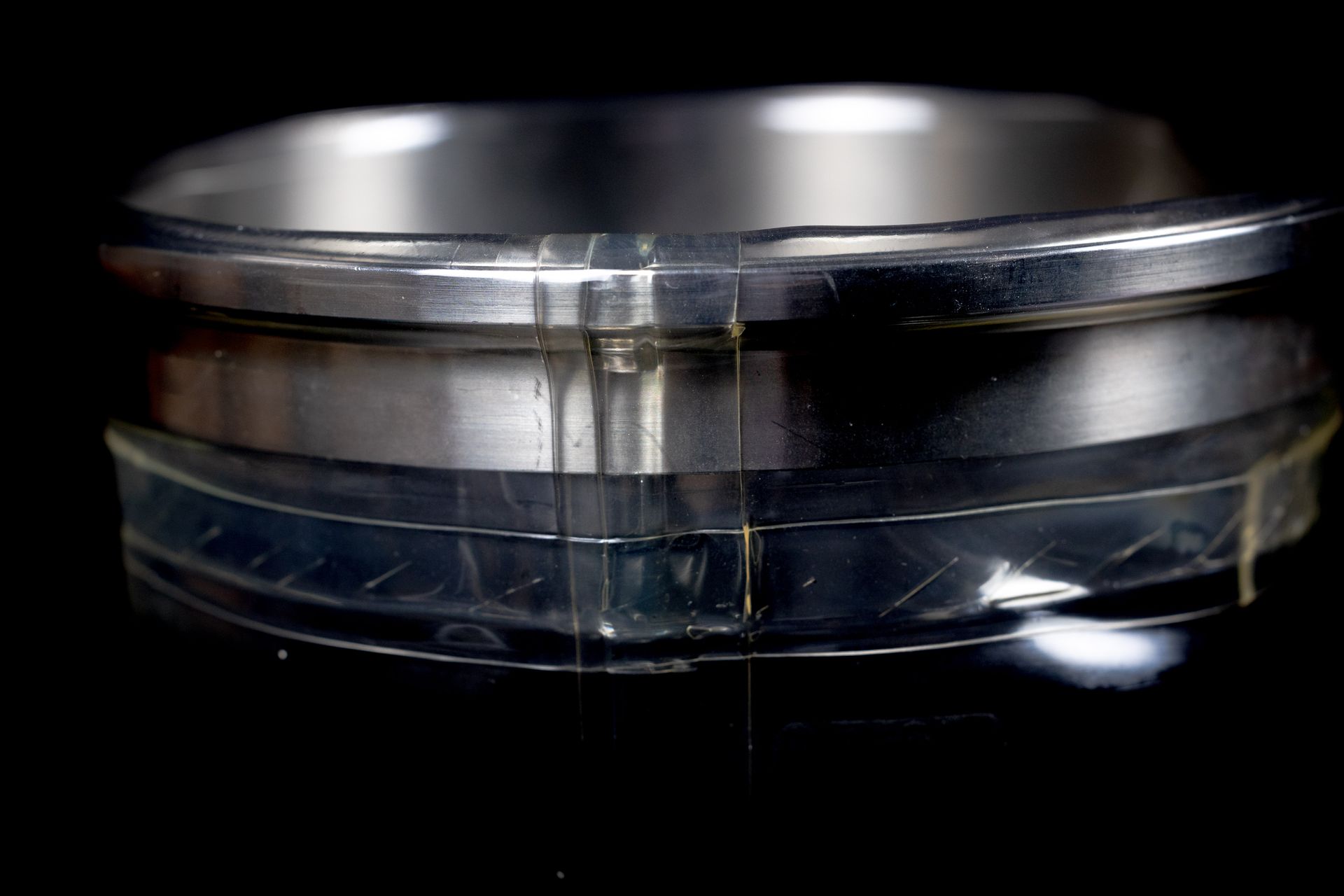

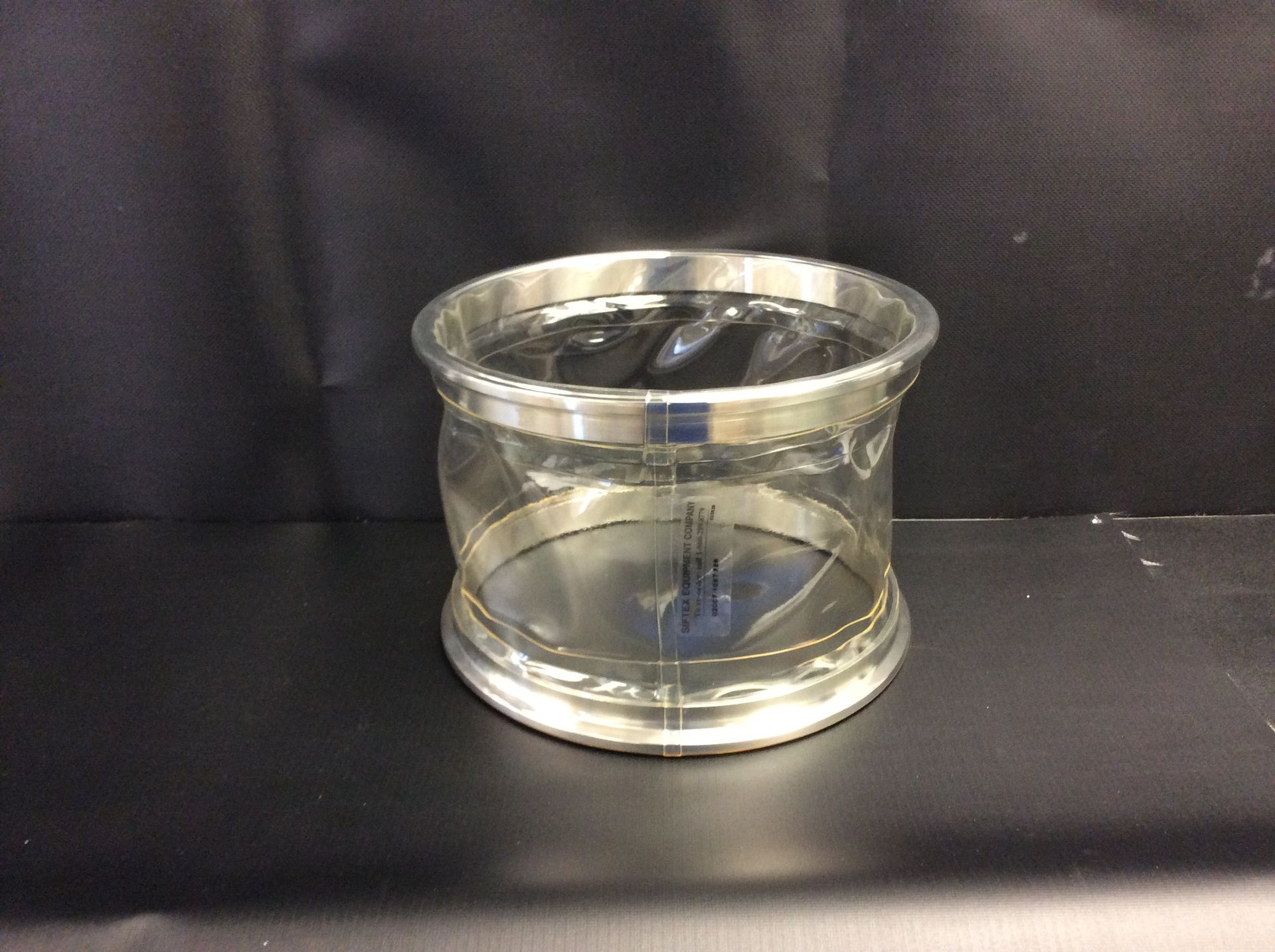

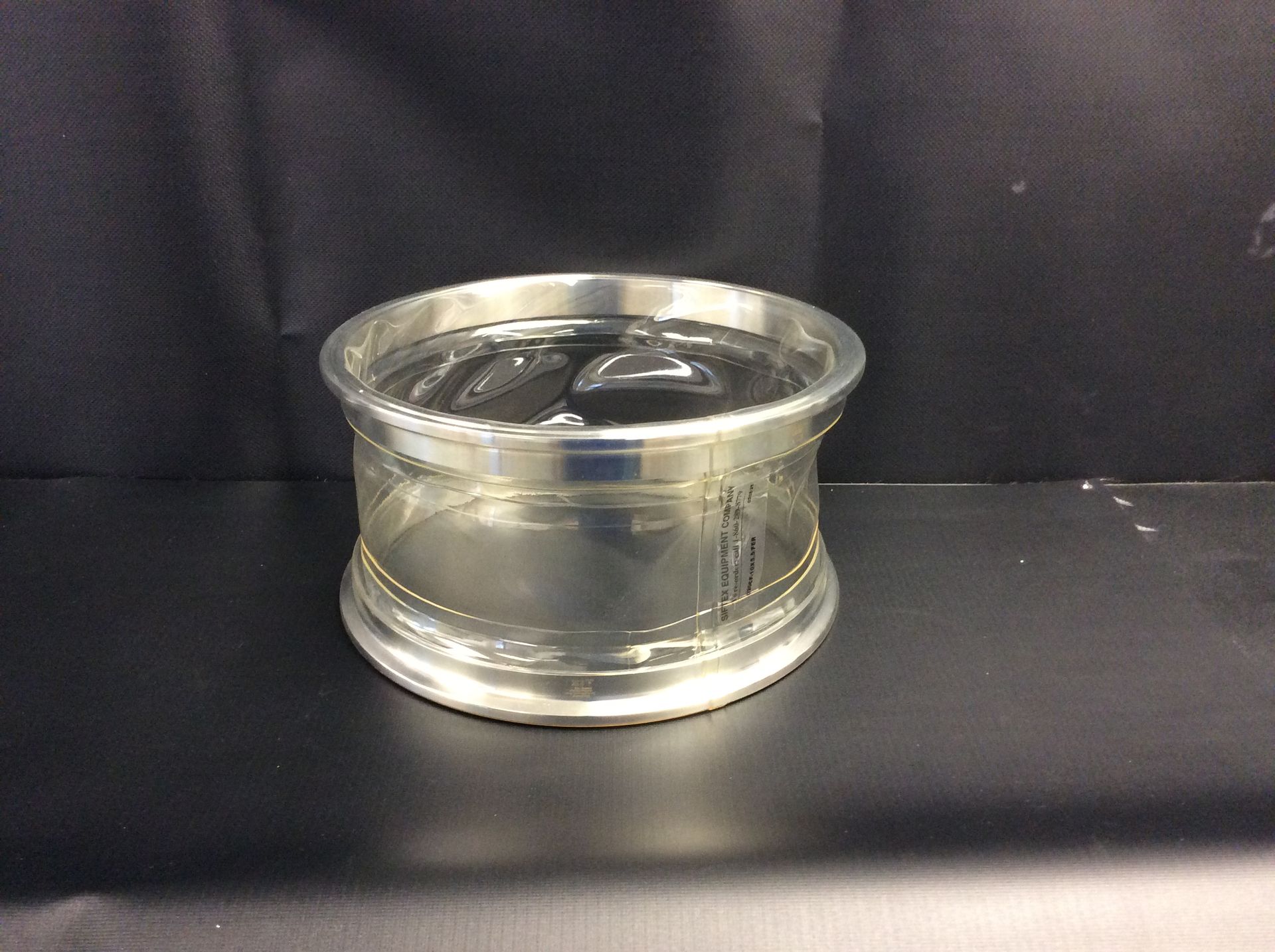

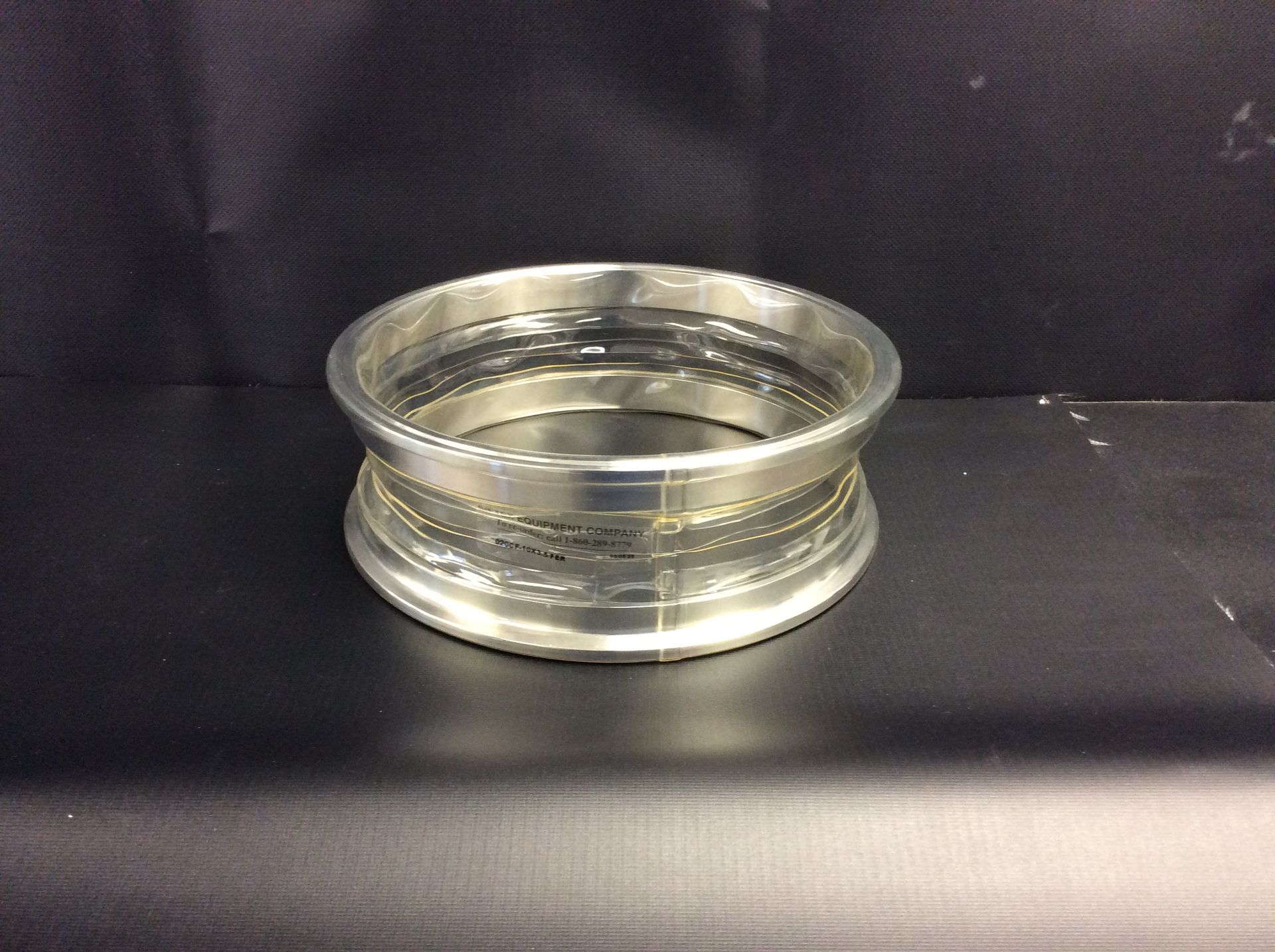

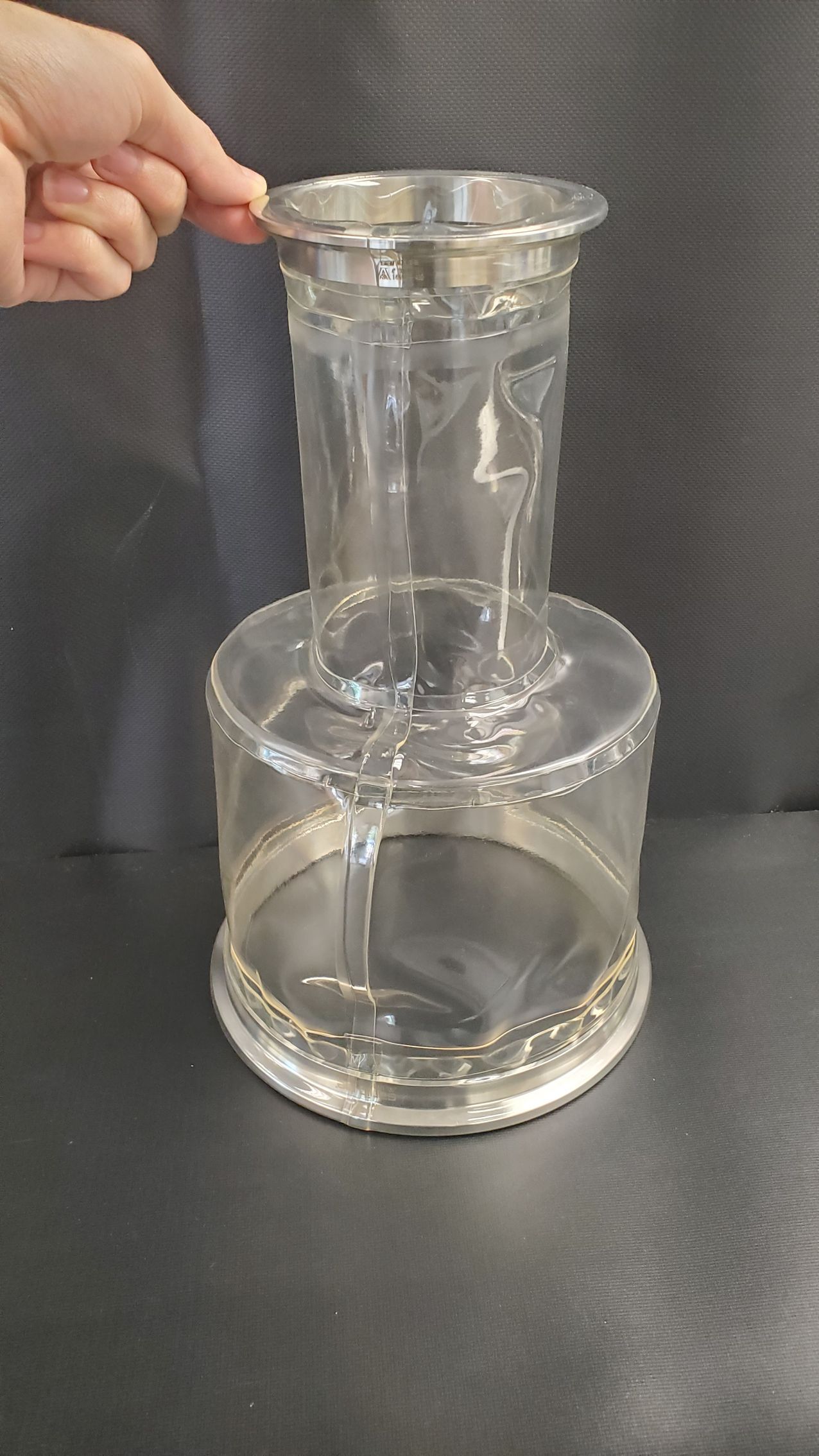

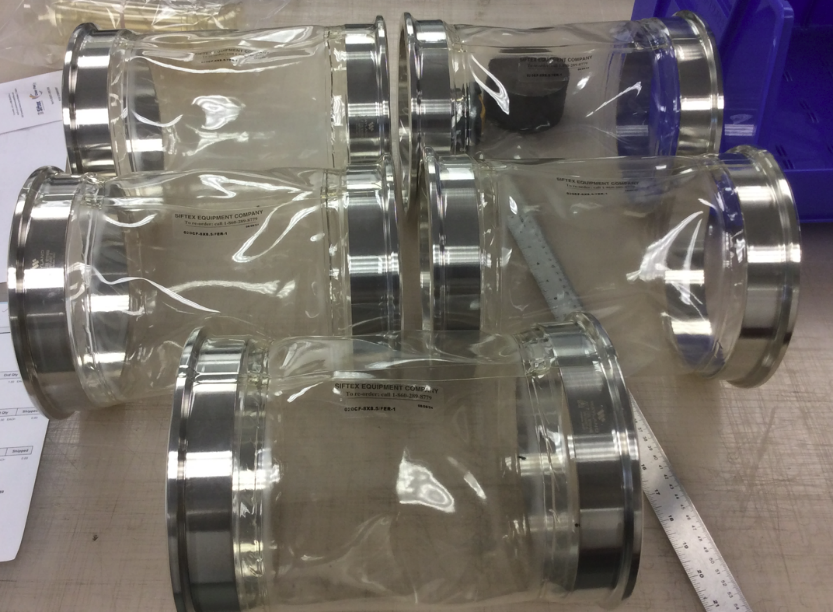

Tri-Clamp Connectors

Description:

Tri-Clamp Connectors offer a fast, sanitary, and secure solution for flexible connections in processing environments. Available in polyurethane, silicone, and other materials, they are custom-built to meet the demands of industries like pharmaceutical, food, and chemical processing. Designed for easy assembly and breakdown, these connectors help minimize downtime while ensuring compliance with strict hygiene standards. Standard diameter sizes of 3", 4", 5", 6", 8", 10", and 12" are available. Lengths are fully customizable to fit your specific equipment and process line configurations.

Learn more:

Reach out to Siftex today to discover more about our Tri-Clamp Connectors and find the perfect fit for your machinery's needs.

Start Your Custom Project With Us Today

Embark on a journey to innovate and excel with our tailor-made industrial solutions. Connect with our experts now to elevate your operations with customized, precision-engineered products.